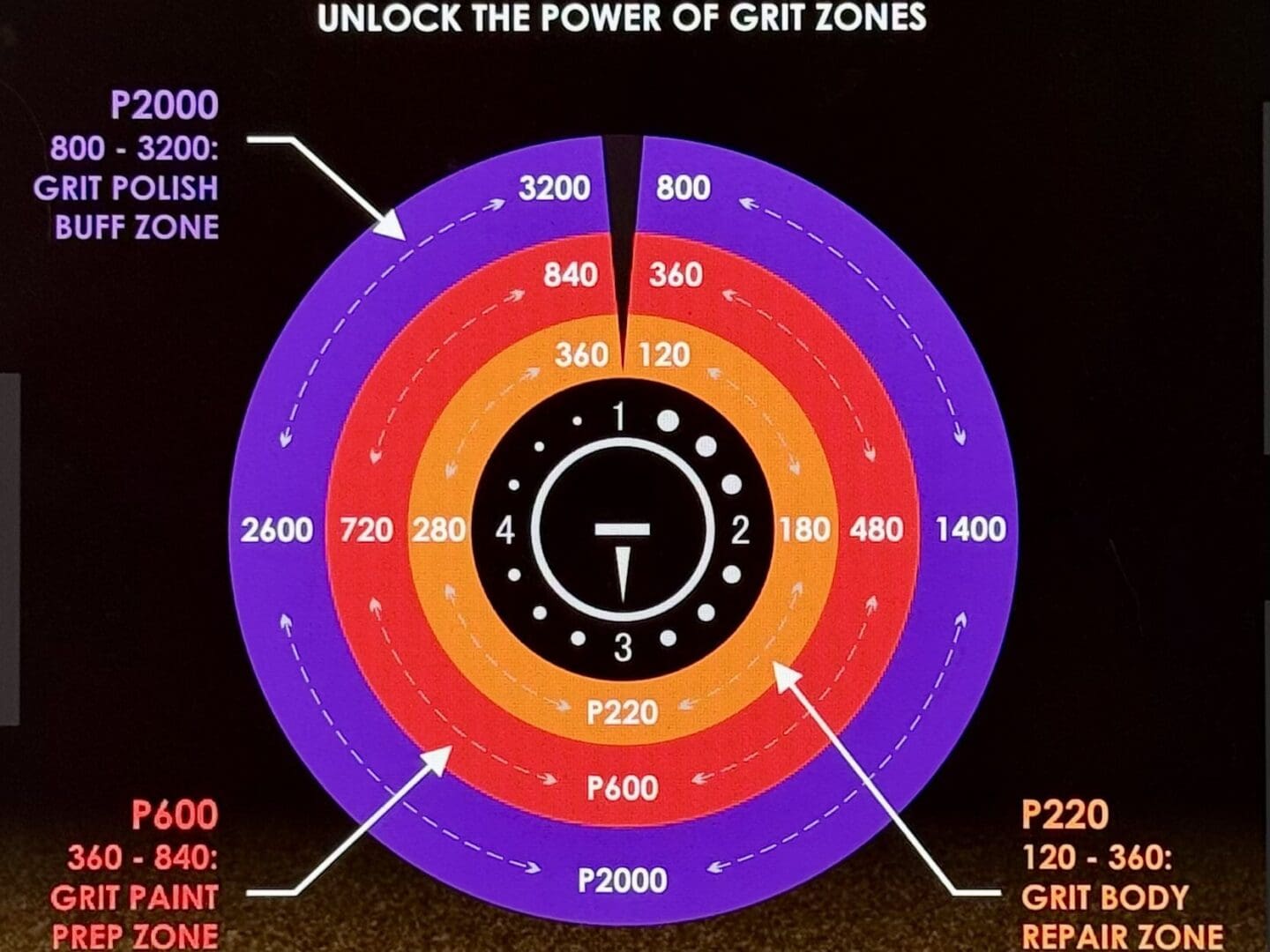

Unleash The Power Of Grit Zones

Surface Smoothness

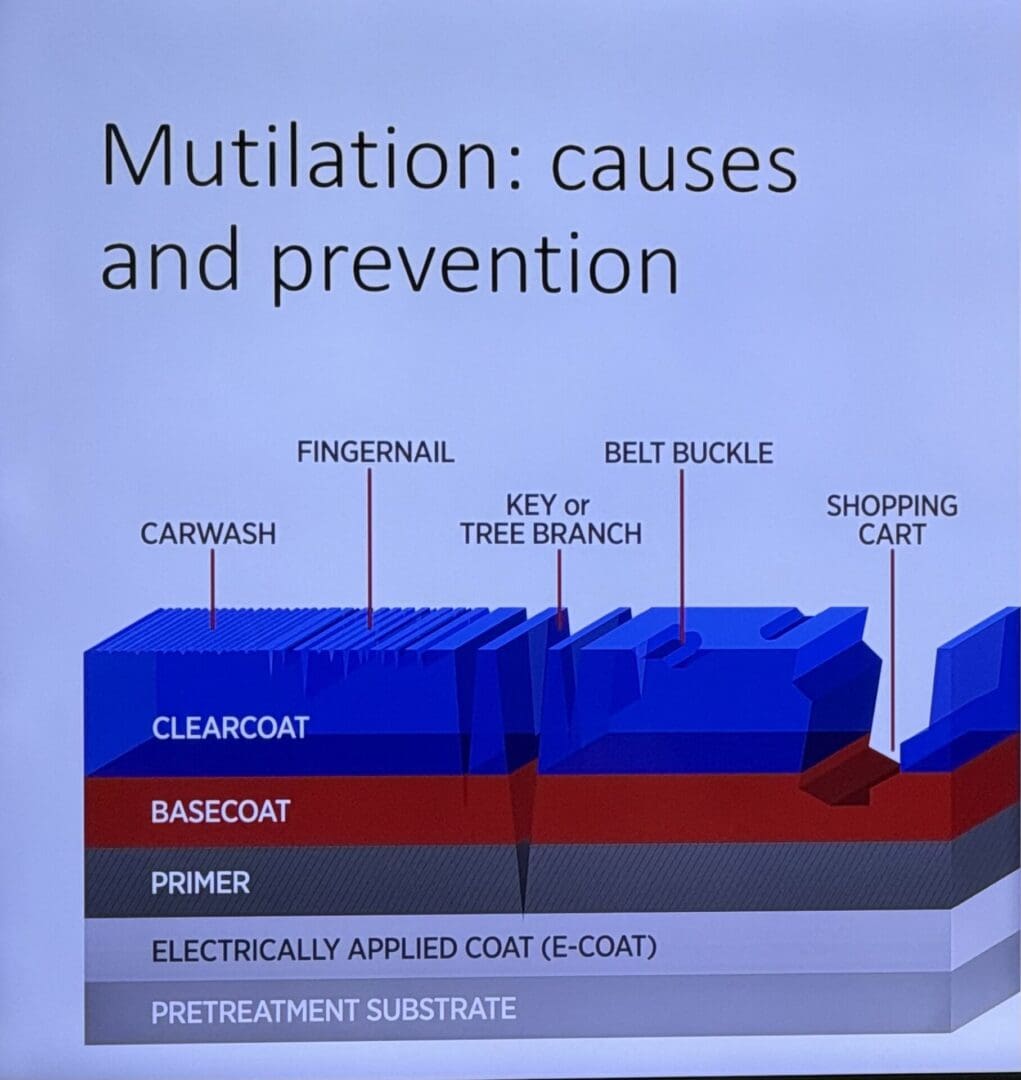

- Eliminates defects in the primer, such as drips, runs, or uneven application.

- Ensures a flat, professional-looking surface for the paint to adhere to.

Feathering Edges

- Blends the primed area seamlessly with the surrounding surface.

- Prevents visible transition lines in the final paintwork.

Ensured Adhesion

- A well-prepared primer surface maximizes paint adherence.

- Reduces the risk of peeling, flaking, or bubbling over time.